Hydraulic Static Dynamic Stable Internal Centerless Grinding Machine FX-18CNC

Device description:

1. The body and components are cast by Milhanna high grade cast iron FC30, which is artificially normalized heat treatment and then treated by natural aging. Components are processed by YASDA, MITSUI SEIKI, TOSHIBA, ELB and other world-class equipment once clamping processing. Precision size can be up to micron level, to ensure high precision equipment basic components.

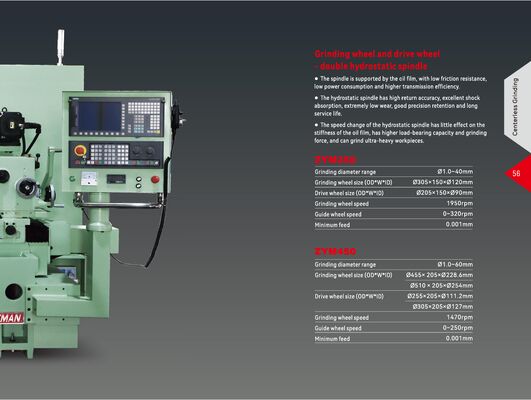

2. The spindle adopts a self-developed double static pressure front support spindle with pure liquid friction, small friction resistance, low power consumption and high transmission efficiency; during normal operation and frequent starts, no wear caused by direct contact between metals occur, and accuracy is maintained good lifetime is long; since the floating of the shaft is achieved by the pressure of external oil, it has a high load-bearing capacity under various relative motion speeds, and speed changes have little impact on the stiffness of the oil film; lubricating oil layer It has good anti-vibration performance, and the shaft runs smoothly; the oil film has the function of compensating errors, which can reduce the impact of errors caused between the shaft and the bearing itself, and the rotation accuracy of the shaft is high.

3.The regulating wheel spindle uses a servo motor of brand Delta, with freely variable speeds ranging 0-250 rpm (digital control), and the optimum and constant linear speed can be kept even when the diameter of regulating wheel is changed owing to wearing, bringing the best grinding quality.

The servo motor is smartly assembled in the regulating wheel holder, and drives the spindle directly through synchronous belts, with the same tilting angle as the regulating wheel, to keep the two belts parallel all along, which can avoid inertia loss, and some other inconvenience brought by the old-type chain transfer system. No chain or spring has to be changed often as before.

4. The spindle automatic lubrication circulating oil (high-grade spindle oil 10#) and the hydraulic dressing device are from the same oil pump, with an external oil tank, making it easy to clean and change the oil. The spindle circulating oil is filtered by two oil filtering devices and equipped with a pressure controller to ensure the life of the spindle. The cooling adopts a double-circuit cooling system to ensure the constant temperature of the spindle oil.

5.It adopts a double flat rail guide structure, 90mm wide flat rail sliding, the bottom plate is designed with a curved oil filling groove, a lubricant return channel is set between the track surfaces, and the feed slide is covered with wear-resistant glue, which reduces the friction coefficient to a great extent It greatly reduces the wear of the track surface, increases the feed speed, improves the contact rigidity, makes it easier to replace the wear-resistant rubber for later wear, and increases the service life. The flat track surfaces are all subjected to high-frequency heat treatment to improve the wear resistance.

6. The overall electric circuits use the electric system of Japanese Fuji company, with good operations as well as beautiful appearance. The bigger and taller electric cabinet is convenient for operation and heat radiation.

7.The CNC software is further developed by Hotman, and the interactive HMI (Human Machine Interface) is easy for learn and operation. Equipped with brand new servo motor, wheel feeding as one axis and CNC form dressing as a second axis. There is good compatibility among the servo motor and the axis, and the wheel feeding is precise.

|

No.

|

Item

|

Unit

|

Model ZYM450

|

|

1

|

Grinding diameter

|

mm |

Φ 1-60 |

|

2

|

Grinding wheel sizes (OD*W*ID)

|

mm |

Φ455x205xΦ228.6 |

|

3

|

Regulating wheel sizes (OD*W*ID)

|

mm |

Φ255x205xΦ111.2 |

|

4

|

Grinding wheel spindle speed

|

RPM |

1470 |

|

5

|

Regulating wheel spindle speed

|

RPM |

0-250 |

|

6

|

Grinding wheel spindle motor

|

KW |

18.5 |

|

7

|

Regulating wheel spindle motor

|

KW |

3 |

|

8

|

Feeding servo motor

|

KW |

2.4 |

|

9

|

Dress servo motor

|

KW |

1.0*2 |

|

10

|

Hydraulic pump driving motor

|

KW |

0.75 |

|

11

|

Cooling pump driving motor

|

KW |

0.37 |

|

12

|

Regulating wheel feeding hand-wheel

|

mm |

3.5/rev., 0.05/gra.

|

|

13

|

Regulating fine turning hand-wheel

|

mm |

0.1/rev., 0.001/gra.

|

|

14

|

Worktable feeding hand-wheel

|

mm |

feeding minimum |

|

15

|

Worktable fine turning hand-wheel

|

mm |

0.2/rev., 0.001/gra.

|

|

16

|

Dress feeding hand-wheel

|

mm |

2/rev., 0.01/gra.

|

|

17

|

Tilt angle of regulating wheel

|

Deg |

+5°~-3° |

|

18

|

Return angle of regulating wheel

|

Deg |

±5° |

|

19

|

Machine sizes (L*W*H)

|

mm3 |

450×1200×2000 |

|

20

|

Machine weight |

KG |

approx. 3500 |

Hotman specifications (Grinding wheel depends on the part material)

|

No.

|

Grinding method

|

Part

|

Roundness

|

Roughness

|

| 1 |

Through grinding

|

Standard part

|

≤0.001mm |

≤Ra0.1 |

| 2 |

In grinding(Press)

|

Standard part

|

≤0.002mm |

≤Ra0.2 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!