Product Description:

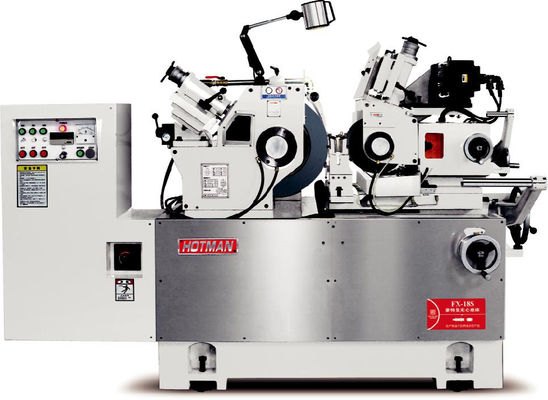

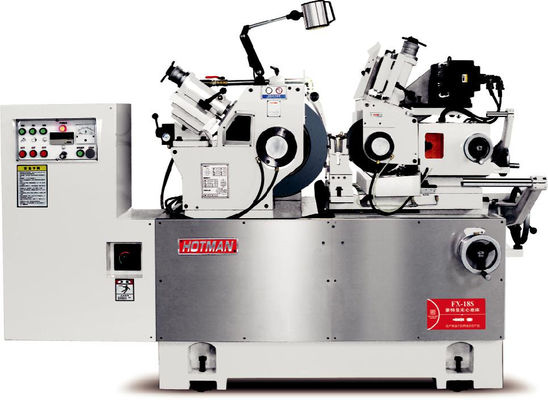

The Centerless Grinding Machine is a versatile and efficient piece of equipment used for precision grinding operations. With mechanical dimensions measuring 2350×1960×1550, this machine offers a compact yet sturdy build suitable for various industrial applications.

Equipped with a high-quality Grinding Wheel Spindle Bearing available in Ceramic or Steel options, this Centerless Grinding Tool ensures smooth and precise grinding results. The choice of bearing material allows for enhanced durability and performance, catering to different operational requirements.

One of the standout features of this Centerless Grinding Device is its Automatic Machine Guide Rails Lubrication system. This innovative mechanism helps in maintaining optimal lubrication levels on the guide rails, ensuring smooth movement and reducing friction during the grinding process. The automatic lubrication feature also contributes to the machine's overall efficiency and longevity.

Precision is paramount in grinding operations, and the Grinding Wheel Spindle Accuracy of 0.001mm on this machine ensures exceptional grinding precision. This high level of accuracy allows for the production of finely finished components with tight tolerances, meeting the most demanding quality standards in various industries.

The Grinding Wheel Motor Power of 2-15KW provides the necessary force and control required for efficient material removal during grinding operations. Whether handling light or heavy-duty grinding tasks, this machine offers a range of motor power options to suit different application needs, making it a versatile solution for a wide variety of grinding projects.

In summary, the Centerless Grinding Machine is a reliable and high-performance tool for precision grinding tasks. With its robust mechanical design, choice of premium spindle bearings, automatic lubrication system, exceptional accuracy, and variable motor power options, this machine offers a comprehensive solution for industries requiring efficient and precise grinding capabilities. Whether used for small-scale production or large-scale manufacturing, this Centerless Grinding Equipment delivers consistent and high-quality results, making it an essential asset for businesses looking to optimize their grinding processes.

Features:

-

Product Name: Centerless Grinding Machine

-

Device Description: Split Type Automatic Lubrication System High Precision CNC Centerless Grinding Machine FX-18S

-

Packing Size: 2900×2400×1850

-

Spindle Material: SNCM-21H alloy steel

-

Grinding Wheel Spindle Life: 10000-50000h

-

Mechanical Dimension: 2350×1960×1550

Technical Parameters:

|

Grinding Wheel

|

Diamond/CBN

|

|

Mechanical Dimension

|

2350×1960×1550

|

|

Grinding Wheel Spindle Speed

|

1000-3000rpm

|

|

Packing Size

|

2900×2400×1850

|

|

Grinding Wheel Diameter

|

200-500mm

|

|

Product Name

|

High Precision FX-18S CNC Centerless Grinding Machine with Automatic Lubrication System and Stable Grinding Wheel Spindle

|

|

Grinding Feed System

|

V and flat track precision shovel

|

|

Grinding Wheel Motor Power

|

2-15KW

|

|

CNC System

|

Siemens 828D

|

|

Grinding Wheel Hole Diameter

|

100-200mm

|

Applications:

The HOTMAN FX-20G Centerless Grinding Machine is a versatile and high-precision tool that is suitable for a wide range of applications. Here are some Product Application Occasions and Scenarios where the FX-20G can be effectively utilized:

1. Automotive Industry:

The FX-20G is perfect for grinding applications within the automotive industry. It can be used for precision grinding of automotive components such as shafts, gears, and pistons, ensuring high accuracy and quality finish.

2. Aerospace Industry:

With its stable grinding wheel spindle and automatic lubrication system, the FX-20G is well-suited for the aerospace industry. It can be used for grinding aerospace components with tight tolerances and complex geometries.

3. Medical Device Manufacturing:

The FX-20G is ideal for grinding medical device components such as surgical instruments and implants. Its high precision and automatic lubrication system make it a reliable choice for critical medical applications.

4. Precision Engineering:

The FX-20G is a valuable tool for precision engineering workshops. It can be used for centerless grinding of various materials with different hardness levels, providing accurate and consistent results.

5. Tool and Die Making:

The FX-20G is suitable for tool and die making industries where precision is key. It can be used for grinding tools, molds, and dies with high efficiency and repeatability.

With its CE certification and origin in China, the HOTMAN FX-20G Centerless Grinding Machine offers a reliable and high-quality solution for various industries. The minimum order quantity is 1 set, priced at RMB 1 per set with payment terms of T/T. The machine has a supply ability of 30 units with a delivery time of 60 days. It comes in wooden packaging with a weight of 3000KG.

Equipped with a diamond/CBN grinding wheel, the FX-20G, also known as the High Precision FX-18S CNC Centerless Grinding Machine, ensures precise and stable grinding performance. The automatic lubrication system and stable grinding wheel spindle enhance the machine's efficiency and longevity.

In conclusion, the HOTMAN FX-20G Centerless Grinding Machine is a reliable and versatile tool suitable for a wide range of industries and applications. Its automatic lubrication system, stable grinding wheel spindle, and high precision make it an excellent choice for any Centerless Grinding Tool, Centerless Grinding Machinery, or Centerless Grinding Device needs.

Support and Services:

Our Centerless Grinding Machine product comes with comprehensive Product Technical Support and Services to ensure smooth operations and maximum efficiency. Our team of experts is available to provide technical assistance, troubleshooting guidance, and maintenance support to address any issues that may arise.

We offer a range of services including installation assistance, training programs for operators and maintenance staff, spare parts availability, and regular maintenance schedules to keep your machine running at peak performance.

Rest assured that our dedicated technical support team is committed to ensuring your satisfaction and helping you make the most of your Centerless Grinding Machine investment.

Packing and Shipping:

Product Packaging:

The Centerless Grinding Machine is carefully packed in a sturdy wooden crate to ensure safe transportation and delivery. The machine is secured with foam padding to prevent any damage during transit.

Shipping:

We offer worldwide shipping for the Centerless Grinding Machine. Once your order is processed, the machine will be shipped via a reliable freight carrier to your specified address. You will receive a tracking number to monitor the delivery status of your machine.

FAQ:

Q: What is the brand name of the Centerless Grinding Machine?

A: The brand name is HOTMAN.

Q: What is the model number of the Centerless Grinding Machine?

A: The model number is FX-20G.

Q: Where is the Centerless Grinding Machine manufactured?

A: The machine is manufactured in China.

Q: What is the minimum order quantity for the Centerless Grinding Machine?

A: The minimum order quantity is 1 set.

Q: What are the payment terms for purchasing the Centerless Grinding Machine?

A: The payment terms are T/T.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!