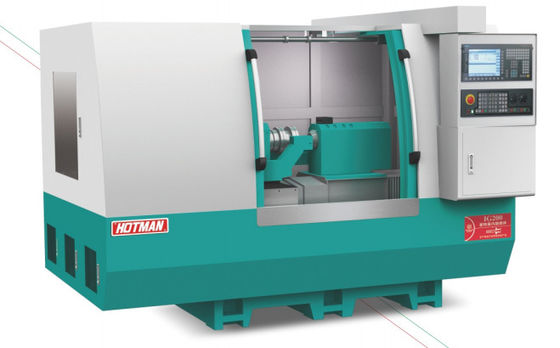

High precision CNC internal grinder IG200

Product Description:

The Internal Grinder Machine is a highly advanced technology designed to perform precise internal grinding operations. With a grinding wheel diameter of 200mm, a table size of 400mm, and a grinding wheel feeding motor accuracy of 0.005mm, it is capable of grinding workpieces ranging from 50 to 200mm in size. The grinding wheel feeding motor speed is adjustable from 50 to 1000rpm, ensuring precise and accurate grinding results. The Internal Grinder Machine is the perfect choice for any internal grinding needs, with its advanced internal grinder technology, precise internal grinder assembly, and highly reliable internal grinding machine.

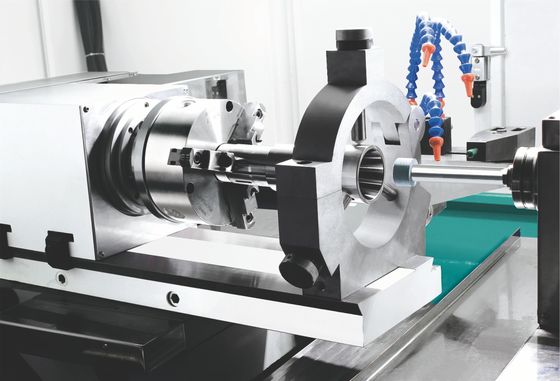

The machine body and main components are made of high-grade cast iron FC-30, which has been artificially normalized heat treated and then subjected to natural aging treatment. The body and components are processed using YASDA, MITSUI SEIKI, TOSHIBA, ELB and other world-class equipment for one-time clamping processing, and the precision dimensions can reach the micron level. All sliding surfaces, contact surfaces and guide rail surfaces adopt manual grinding and scraping technology to ensure the long-term accuracy and stability of the machine.

An automatic centralized lubrication system lubricates the machine linear guides and ball screws continuously, which makes sure longer service life and high precision. The cooling system is separated with machine body, which eliminates vibration and helps heat radiation.

The grinding wheel spindle adopts an electric spindle with the characteristics of high speed, high precision, high rigidity, low vibration, low noise and low temperature rise. The driving system is cooled by a water cooling system to ensure that the grinding wheel headstock always works in a thermally stable state, making the grinding wheel more stable, and working efficiency is doubled. According to the processing needs, electric spindles with different speeds of 24000-60000rpm are optional; for workpieces with deep inner circles, an integrated spindle can be customized to achieve precision grinding.

It adopts German Siemens CNC system and has undergone further development. It has a user-friendly human-machine dialogue operation interface and is equipped with Siemens high-performance servo motors, which makes the equipment CNC system and transmission system have better compatibility. It also has automatic sand dressing and automatic offset function, which ensures the stability and accuracy of feed and grinding.

Features:

- Product Name: Internal Grinder Machine

- Internal Grinding Machinery: 50-1000rpm

- Internal Grinding Mechanism: 400mm

- Internal Grinding Mechanism Motor Speed: 0.75KW

- Table Size: 0.75KW

- Grinding Wheel Feeding Motor Power: 0.1-3m/min

Technical Parameters:

| Project |

Parameter |

| Processing capacity |

|

|

Grinding aperture range

|

Φ6~φ200mm |

|

Maximum grinding depth

|

170mm |

|

Maximum outer contour diameter of grinding workpiece

|

220mm |

| Grinding diameter |

400mm |

|

Mounting chuck specifications

|

6 "hydraulic chuck/manual chuck

|

|

Angle of head box rotation

|

Two degrees before and 20 degrees after |

| Grinding wheel spindle parameters |

|

|

Inner hole grinding spindle power

|

7.5KW |

| Linear speed of grinding wheel |

20~30m/s |

|

Head frame spindle parameters

|

|

| Spindle speed |

50-1500rpm |

| Spindle form |

Sleeve structure bearing spindle

|

| Cone-hole specification |

MT-5 |

| Spindle drive mode |

Servomotor |

| X axis (workpiece spindle) |

|

| X-axis feed stroke |

410mm |

| X axis fast moving speed |

0.1~10mm/min |

|

X-axis feed minimum resolution

|

0.001 |

| X axis servo motor power |

2.2 KW |

| Z-axis (workbench) |

|

|

Z axis axis fast moving speed

|

0.1~10mm/min |

|

Z-axis feed minimum resolution

|

0.001mm |

|

Maximum travel of Z axis

|

410mm |

|

Z-axis servo motor power

|

2.2KW |

Applications:

HOTMAN IG200 Internal Grinding Device: The HOTMAN IG200 Internal Grinding Device is a reliable and efficient machine for precision grinding of internal surfaces. The 0.75KW grinding wheel feeding motor power ensures a powerful and accurate grinding operation, with a repeatability of 0.001mm. The machine is capable of grinding workpieces of size ranging from 50-200mm, at a table speed of 0.1-3m/min. Its grinding wheel feeding motor accuracy is 0.005mm, making it ideal for high precision internal grinding operations. This internal grinding machine is the perfect choice for any application that requires precise and accurate grinding of internal surfaces.

Support and Services:

Technical Support and Service for Internal Grinder Machine

At XYZ Company, we understand the need for reliable technical support and service for all our products, including our Internal Grinder Machine. We have a team of experienced technicians who are available to provide on-site and telephone support to our customers. Our technicians are knowledgeable in the operation and maintenance of the Internal Grinder Machine, and they can quickly diagnose and resolve any issues that may arise.

In addition, we provide regular maintenance services for our Internal Grinder Machine, which include checking and replacing worn parts, lubricating moving parts, and calibrating machine settings. Our technicians can also provide recommendations on how to improve the performance of the machine and how to extend its lifespan.

For any questions or concerns about our Internal Grinder Machine or its technical support and service, please feel free to contact us. We are always happy to help.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!