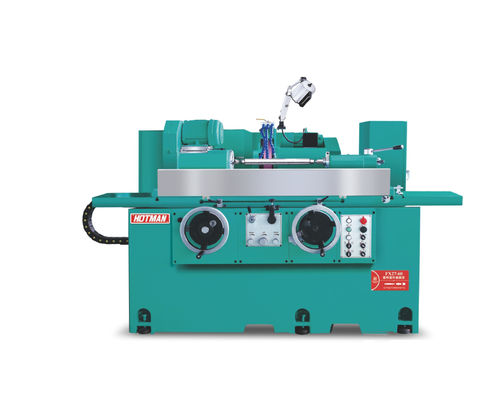

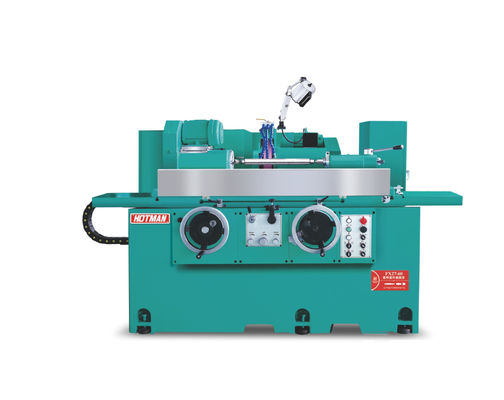

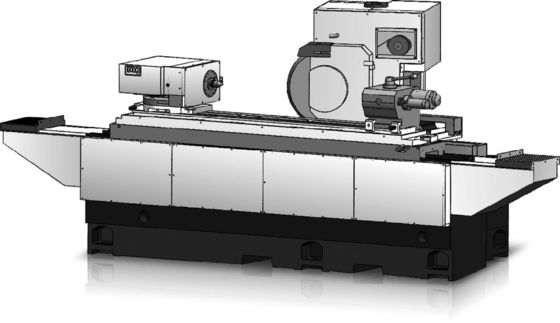

Cylindrical Grinder Grinding Form

Device description:

1. The body and components are cast by Milhanna high grade cast iron FC30, which is artificially normalized heat treatment and then treated by natural aging. Components are processed by YASDA, MITSUI SEIKI, TOSHIBA, ELB and other world-class equipment once clamping processing. Precision size can be up to micron level, to ensure high precision equipment basic components.

2. Machine guide rails and precision ball screws are continuously lubricated by automatic lubrication system to ensure longer service life and accuracy. The cooling system is separated from the body to eliminate vibration and favorable heat dissipation.

3.Equipped with Siemens 828D CNC automatic grinding system, and secondary development, man-machine dialogue fool operation, with many optional equipment to choose from, including inner hole grinding device, automatic end measuring device, automatic outside diameter measuring device, etc.

4. The grinding feed system is composed of a V and a flat track of hand-crafted precision shovel, with automatic lubrication system and C3 level precision grinding ball screw, which can achieve smooth movement, excellent repeated positioning accuracy and long track life.

5. The standard configuration of the grinding wheel spindle is rear four and rear two bearing structure. High precision dynamic and static pressure spindle can also be selected, which has the characteristics of high rotation precision, high dynamic stiffness, good vibration resistance, high grinding efficiency and good grinding surface quality. For special work-piece grinding, the grinding wheel speed can be adjusted, up to 3500 RPM and 60m/s.

6. The tail seat is designed to be both rigid and robust. A hardened alloy steel sliding cylinder encrusted in the cast iron body is designed to carry the MT4 top core. The jacking force of the sliding cylinder can be easily changed by adjustment knobs at the rear. Special accessories oil pressure tail seat with a pedal to facilitate unloading work parts.

7.Siemens numerical control system as the standard configuration, after secondary development, all Chinese operation interface, easy to use. Equipped with Siemens high performance servo motor, the equipment CNC system and drive system have better compatibility, at the same time with automatic sand repair and automatic compensation function, to ensure the stability and precision of feed and grinding.

Technical specification:

| Project |

Unit |

Model:FX32P-60CNC |

|

Processing capacity

|

Maximum rotating diameter of table |

mm |

320 |

|

Maximum distance between

two thimbles

|

mm |

600 |

| Maximum grinding diameter |

mm |

320 |

| Maximum load between two parietal hearts |

Kg(b) |

60(top work)/20 (working head only) |

| Grinding wheel size (diameter × width × aperture) |

mm |

455×38(32-50)×127 |

| Grinding wheel speed |

rpm |

1650 |

| Maximum linear speed of grinding wheel |

m/s |

40(high speed grinding wheel up to 65) |

| |

Grinding wheel dressing |

mm |

Automatic type |

|

Grinding wheel head

|

Feed Angle |

Deg |

90 |

| Feed stroke |

mm |

250 |

| X axis fast moving speed |

m/min |

6 |

| Minimum X-axis feed |

mm |

0.001 |

|

Head frame

|

Spindle speed |

rpm |

50-500 |

| Spindle form |

|

Simultaneous or centering |

| Thimble specification |

|

MT-4 |

|

Tail seat

|

Automatic telescopic distance |

mm |

40 |

| Thimble specification |

|

MT-4 |

|

worktable

|

Z axis fast moving speed |

m/min |

8 |

| Minimum z-axis feed |

mm |

0.001 |

| Maximum travel |

mm |

550 |

| Angle of rotation |

Deg |

+ 6/-9 |

|

Motor

|

Grinding wheel spindle motor |

KW |

3.75/5.5 |

| X-axis feed motor (servo) |

KW |

2.2 |

| Z-axis feed motor (servo) |

KW |

2.2 |

| Head frame spindle motor |

KW |

0.75 |

| Cooling pump motor |

KW |

0.75 |

| Lubricating oil motor |

KW |

0.25*2 |

| Tail stock oil pump motor |

KW |

0.75 |

|

Other

|

Net machine weight |

Kg |

3300 |

| Gross machine weight |

Kg |

3500 |

| Package size (length * width * height) |

mm |

2800*2000*2000 |

A. Straight in grinding:

Small production, automatic feed with no spark timer, can get good grinding quality mass production, add automatic outside diameter measuring device (special accessories), can provide the best yield and grinding effect (CNC models).

B. Transverse grinding:

Automatic intermittent feed and hydraulically driven table enable the most efficient transverse grinding of the work object.

C .End grinding:

Remove the rotating cover of the working spindle head and replace it with a three or four claw chuck. Change the position of the positioning tip to make the chuck rotate, and fix it at the position of 90° for end grinding.

D. Shoulder grinding:

When the outer diameter of the working object and its shoulder are grinding to be completed at one time, the working object is supported by the two top center and the grinding wheel is refitted on the right side of the grinding wheel head and rotated at an Angle to grind.

E .Oblique grinding:

The working object can be supported by the chuck or the two top center, and the table and the grinding wheel head can be rotated and adjusted easily.

F .Inner diameter grinding:

Inner diameter grinding accessories (special accessories) Grinding inner diameter, as long as the inner diameter grinding spindle is pulled down and fixed in the grinding position can be grinding.

Inner hole grinding device (optional):

Rotational speed Inside diameter range Maximum depth

20,000rpm Φ25~45mm 100mm

30,000rpm Φ 12~25mm 60mm

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!